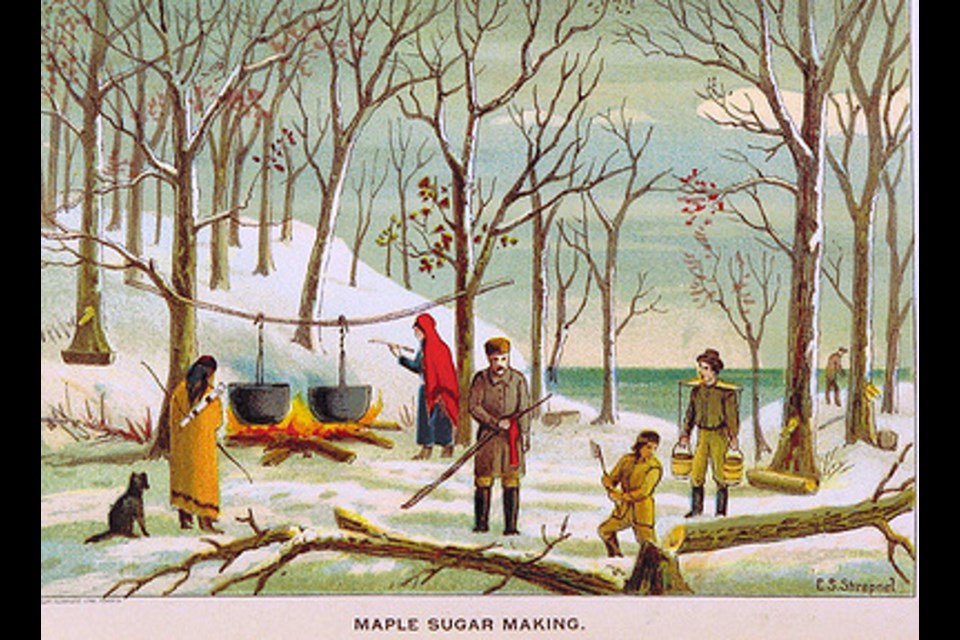

Let's examine a fun topic, you may say a "sweet topic." Maple sugar was an important commodity for our early pioneers and, as was so often the case, the knowledge of maple sugar production came to us from our Indigenous peoples who shared the secret with our ancestors. Would our early settlers have survived life in the new world without their help? Doubtful.

In our early history, a comparatively small amount of coarse sugar cane was imported into Canada and that was generally only to the larger centres, and the cost was often prohibitive. Many of our settlers obtained maple sugar from the Indigenous in trade, but it was soon to become a part of every family’s home routine. If there was a sugar bush nearby, then the spring sugar-making operation became part of their home chores.

The first settlers to this country around 1600 discovered the native peoples extracting maple sugar from the surrounding forests. The sweet sap of the sugar maple (acer saccharum) was known and valued by the Indigenous of the Eastern Woodlands, including the Abenaki, Haudenosaunee and Mi’kmaq, long before the arrival of European settlers.

Haudenosaunee tradition tells of the piercing of the bark of the maple tree and the use of its “sweet water” to cook venison, perhaps an early example of the establishment of the culinary technique of maple-cured meats. Maple curing was a food preservation method practised by the Anishinaabe that allowed communities to keep food stores for winter months when food was scarce.

The Anishinaabe called it the “sugaring off” period when sap was collected during the “maple moon” or “sugar month.” This tradition of sugaring off became established in communities in the deciduous forests of North America and has survived to the present day.

When the Jesuits missionaries began their work among the Indigenous peoples, they reported back that the local peoples "extract a certain liquid that runs from the trees towards the end of winter." In Jesuit Relations, Father LeJeune writes in 1634 that the native peoples, during a period of food scarcity, chew the bark of a tree for substance, a food they call ‘micktan’. He also spoke of how they "split the tree" and collected its juices, a substance akin to honey or liquid sugar.

The Indigenous people would gash the tree in a slanting direction with a tomahawk and then insert a wooden chip or spout that directed the sap into a birch bark receptacle on the ground. The Mohawks used a hollowed-out basswood log as a sap trough after having burned it out and then scraped it smooth with a stone adze.

There were two methods of sap boiling. The first was using earthenware pots over an open fire. They also employed a method of boiling involving the heating of rocks in the fire and then dropping them into the sap trough until the sap had been reduced. This method was labour intensive, as you can imagine. The amount that could be produced using these methods was limited but the sugar produced was highly prized as a food source.

With the arrival of the fur traders, the Indigenous obtained iron kettles, and began producing sugar in a similar way to how the early settlers would later do it.

Early records recall how in early April the females would move to a temporary camp near a maple grove or sugar bush and began to set out the troughs and firewood, along with the kettles, in preparation. Thomas Need, a fur trader, recalls how in 1835 near Pigeon Lake, he watched the Indigenous tap the trees in a systematic way.

He records that each family seemed to have their own maple plot consisting of three to four trees. The young were assigned the task of collecting the sap and transporting it to the large kettles on huge communal fires.

He also recalled there were those among the group who were experts on regulating the heat and cooling the liquid to produce the best results. Everyone had a task from stirring to storage within the group.

I found one thing every interesting. It seems they had adopted the edict that if you did not participate in the labour, then you could not enjoy the benefits of the endeavour. Excess sugar was then traded or sold to the settlers and provided a nice income apparently.

There are many stories of local tribes bringing sugar as a gift to settlers or traders as a sign of friendship. It is important to remember our forefathers counted on the lessons from the Indigenous peoples to survive. If one reads any of the accounts from back then, you will note that the secrets of hunting, fishing, agriculture, food preparation and local medicines were freely shared. My family records allude to the fact that my people would likely not have survived without the knowledge shared by the native peoples.

We know that sugar making was a well-organized industry among the Indigenous. The sugar would arrive neatly packed in birch baskets, pre-weighed and ready for market. John Graves Simcoe’s wife writes in her diary that she purchased 30 pounds of maple sugar for $3. She also tells us that in a good year, according to the supplier, a camp could produce between 300 to 400 pounds of sugar.

It seems that these mokuks or packages of sugar came in a variety of quantities from 20 to 70 pounds. The cost to the merchants in the early 1830s was six cents per pound, payable usually in merchandise. These mokuks would often find their way to Montreal, where they would be further refined into fine brown sugar. Records from the Holland Landing area speak of shipments arriving from the Manitoulin area by water.

That is not to say that the early fur traders and settlers didn’t manufacture their own sugar using the Indigenous recipe. Alexander Henry, an early fur trader just north of us, indicated this sugar became the staple of their diet, the average person eating a pound a day for nourishment. I wonder if any of them had any teeth left.

The methods used by our ancestors changed little from the methods used by our Indigenous neighbours over the years. It really has been only in the last 100 years or so that the process has changed. The schedule followed by our ancestors varied a bit depending on the season, starting as early as late February or as late as the beginning of April. Traditionally, the date of March 20 was the date of commencement locally.

We know a bit about the process of sugar-making locally from accounts published by Col. Samuel Strickland in his treatise The Indian Tribes 1851 to 1856. In it, he tells us that the settler would first clear the sugar bush of any ground cover. The area was fenced in to prevent livestock from grazing and drinking the sap from the troughs as they would often die from drinking too much. A boiling station was constructed in the centre for easy access. The average trough had a capacity of about 100 pails.

We have all likely seen a metal spout or spigot in area trees, but while theirs were made of wood, the same process was followed. The settlers found that an axe damaged the tree, so they preferred an auger to make a half-inch to one-inch hole. The troughs were made of wood, usually pine or black ash, and held about three to four gallons each.

Records show that certain guidelines were put into place through observation. The connection between frosty nights and warm days was noted. The tap worked better on the south side of the tree in the early season and should be moved to the north side later. Copper kettles came into use as well. The boiled liquid needed to be clarified, which involved the removal of earth and other impurities. In the early days, eggs and milk were used to accomplish this task.

Later in the season, the sap was generally used to produce vinegar. Typical of our ancestors, they soon discovered that maple sugar could make a tasty beer after adding a little ginger or spruce nectar to it.

From Mrs. Simcoe’s diary, we learn that sometime the black walnut tree was used for making sugar, something I had never heard before. She credited it with being darker and a bit sweeter.

Strickland indicates that the production of maple sugar was vital to our early settlers, particularly those in the early stages of their settlement. It was this importance that brought about the attention to the preservation of trees, advances in tapping routines, and practical improvements in the processing of the sap.

It is estimated that in the 1840s and 1850s, the average family produced from 1,000 to 5,000 pounds in a good season – that is a lot of sugar. This was to decrease as the century progressed as the business of sugar production was centralized and sugar farms and industrial plants took over production.

The farmer found it economically more efficient to clear his land of the trees and focus on other agricultural processes. The cost of imported sugar went down, and the necessity of family production was thus reduced.

The production of sugar was one of the most laborious processes that the early settler had to undertake. As we know, sugar-making evolved into a seasonal celebration evoking more of a party atmosphere than a food production necessity. As a child, it was certainly a celebratory time for me with sleigh rides and hot cider.

Today, the industry is still strong in Québec, the Maritimes and in Vermont. Canada is the world’s leading producer and exporter of maple products, accounting for 75 per cent of the global market. In 2020, Canadian producers exported more than 61 million kg of maple products, with a value of $515 million. Quebec is by far the largest producer, representing 96.4 per cent of Canadian product exports. World production of maple syrup and sugar is mainly limited to the Maple Belt, the hardwood forest stretching from the midwestern United States through Ontario, Quebec, and New England and into New Brunswick, Nova Scotia and Prince Edward Island; however, British Columbia, Manitoba and Saskatchewan also produce some syrup.

One can still find a good old maple tapping event around our area, more of a celebration then the production of a food necessity.

I wanted to write this article as a testament to the many skills and knowledge that our Indigenous brothers and sisters passed along to my ancestors. In a future column, I want to examine the influence of native medicine in the survival of our kin, a topic that I think is woefully neglected in our history books.

See you all back here next weekend when look at the history of the horticultural society in Newmarket.

Sources: Early Life in Upper Canada by Edwin C. Guillet; The Jesuit Relations and Allied Documents by R. G. Thwaites; Six Years in the Bush by Thomas Need; Diary of Mrs. John Graves Simcoe; The Indian Tribes by Henry Schoolcraft; Travels and Adventures in Canada and the Indian Territories by Alexander Henry; Twenty-Seven Years in Canada West by Samuel Strickland; The Queen’s Bush by W. M. Brown; The Settlement of Upper Canada by William Caniffl Reminiscences of Benjamin Cody, Toronto Telegram, Aug. 1909; The History of Simcoe County by Andrew F. Hunter; Recollections of Pioneer Life, Rachel Haight; Maple Sugar Industry by Leo H. Werner in the Canadian Encyclopedia Online.

Newmarket resident Richard MacLeod — the History Hound — has been a local historian for more than 40 years. He writes a weekly feature about our town's history in partnership with Newmarket Today, conducts heritage lectures and walking tours of local interest, and leads local oral history interviews.